Products

Sheet Metal CNC Fiber Laser Cutting Machine

Sheet Metal CNC Fiber Laser Cutting Machine: High-power fiber laser delivers ultra-precise, burr-free cuts on sheet metal. Advanced CNC system ensures fast positioning and stable performance. Handles diverse thicknesses, boosting productivity for sheet metal fabrication.

Brand:Gain

Product origin:Weifang,Shandong,China

Delivery time:7-30 days

Supply capacity:500 units/year

Send Inquiry

Product Description

Core Performance: Precision & Speed for Sheet Metal Excellence

1.Broad Material & Thickness Range: Handles a full spectrum of sheet metals, including carbon steel (up to 25mm), stainless steel (up to 20mm), aluminum alloy (up to 15mm), brass (up to 10mm), and copper (up to 8mm). Accommodates sheet sizes from 1220×2440mm (standard) to 2000×6000mm customizable, both small-batch customization and mass production.

2.High-Speed Cutting Capability: Equipped with a high-power fiber laser source (1000W–12000W options), it achieves cutting speeds of up to 120m/min for thin sheets (1mm stainless steel) and maintains stable performance for thick plates—reducing processing time by 40% compared to traditional plasma cutters.

3.Ultra-Precise Cutting Quality: Features a high-precision linear guide rail system and servo motor drive, ensuring a positioning accuracy of ±0.02mm/m and repeatability of ±0.01mm. The laser’s minimal spot diameter (0.1–0.3mm) delivers smooth, burr-free edges with Ra ≤ 1.0μm, eliminating the need for secondary grinding or deburring.

Steel Plate Welded Bed

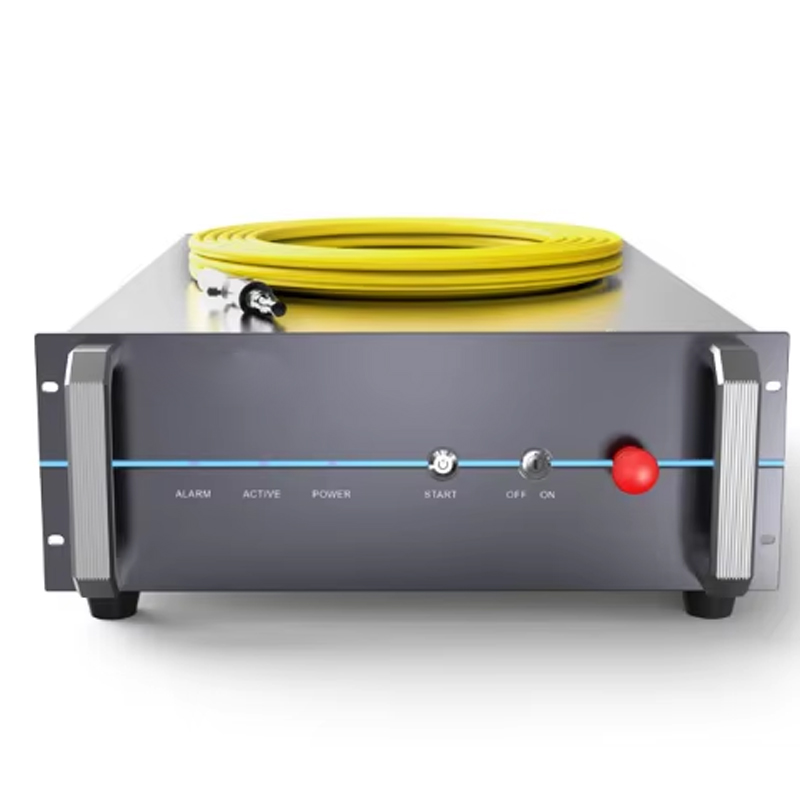

Laser Generator

1.High stability with a service life of up to 100,000 hours.

2.Top-tier after-sales warranty for your peace of mind.

3.The image is for display only; the laser can be customized.

Aluminum Profile

1.Corrosion-resistant and high in rigidity, ensuring high-speed movement during laser processing.

2.While meeting precision requirements, it enables high-speed cutting of various shapes, greatly improving processing efficiency while guaranteeing processing quality.

FSCUT 2000E System

1.One-click cutting

2.Equipped with an automatic nesting function to maximize material savings.

Sample Display

FAQ

How To Use The Machine After Receving The Machine?

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we will send you user manual or videos before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

Why Should You Buy From Us Not From Other Suppliers?

We are professional equipment manufacturer, Our service as below: 1. Factory supply directly 2. 12 months warranty for the whole machine 3. Friendly English version manual and operation video 5. Engineer available to service machinery overs.

What Services Can We Provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW; Accepted Payment Currency:USD,EUR,CNY.

How To Choose A Suitable Machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. It can be customized according to your requirements.

Do You Have A Setup And Equipment Commissioning Service?

Yes,we have. The machine was installed and debugged before delivery. You can use the machine directly after receiving it. Of course, we also could let our technologists go to your country to install and debug.