Products

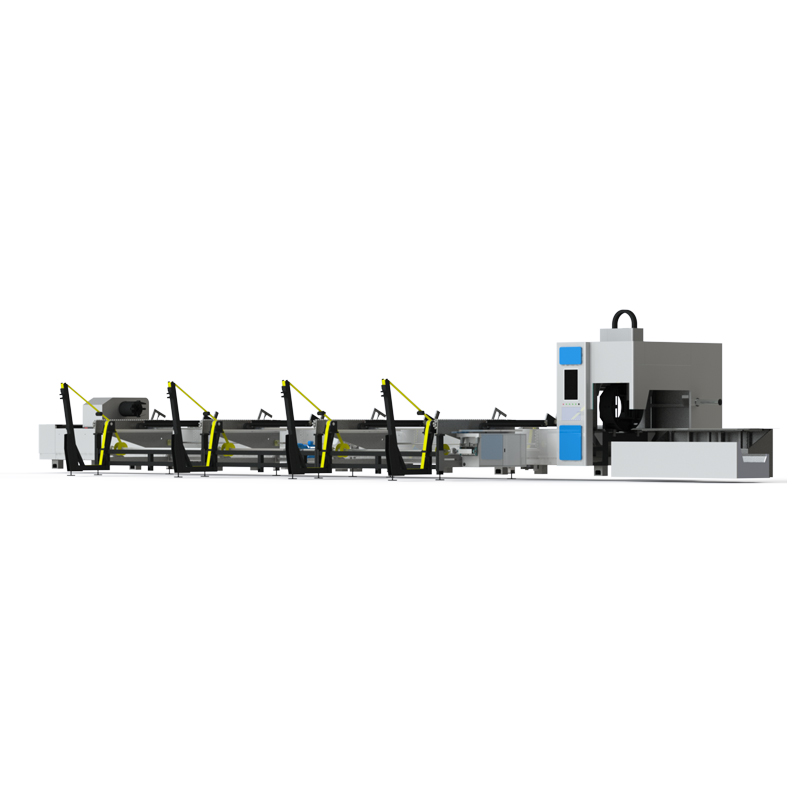

Laser tube cutting machine

This laser tube cutting machine delivers ultra-high precision (±0.03mm) with fiber laser technology. It features auto loading/unloading to boost efficiency by 30%, supports round/square/rectangular tubes (5-200mm), and ensures smooth edges. Energy-efficient, low-maintenance, and ideal for stable mass production in automotive, construction, and furniture sectors.

Brand:Gain

Product origin:Weifang,Shandong,China

Delivery time:7-30 days

Supply capacity:500 units/year

Send Inquiry

Product Description

Product features:

(1)Fully automatic chuck can automatically center and clamp the workpiece immediately. Meanwhile, air pressure can be adjusted to ensure stable and reliable clamping force.

(2)The whole set of servo drive system imported from Japan ensures higher precision, faster speed and more stable operation.

(3)The control system is easy to operate, with more comprehensive compatibility, accurate positioning and efficient cutting.

(4)Laser: imported or domestic brand, stable performance.

(5)Humanized design makes user experience more practical.

(6)Imported electric components.

(7)Ultra low cost, low energy consumption, air assisted cutting of various metal plates.

Technical parameters

| Z axis stroke | 120mm |

| X/Y positioning precision | ±0.02mm/m |

| X/Y Repeat positioning precision | ±0.02mm |

| Max. operation speed | 120m/min |

| Max. acceleration | 1.2G |

| Working voltage | 380V50HZ |

| Notch width | 0.1-0.5mm |

| Notch roughness | Ra3.2 |

| Operation temp. of machine tool | 0℃-40℃ |

| Operation humidity of machine tool | <90% |

| Total power protection level | IP54 |

| Normal model | 6012/6016/6022/6024/6030/6036 |

| Laser power | 1500W/2000W/3000W/6000W/12000W |

Material application:

Carbon steel, stainless steel, galvanized steel, color steel, electrolytic plate, aluminum plate, aluminum alloy, brass, red copper, manganese steel, silicon steel, titanium plate and other metal materials.

Industry application

Kitchen appliances, sheet metal cabinet, mechanical equipment, hardware lighting, door&window manufacturing, advertising signs, auto parts, decoration, shipping and aviation, medical equipment, mining equipment and metal processing industry.

FAQ

How To Use The Machine After Receving The Machine?

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we will send you user manual or videos before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

Why Should You Buy From Us Not From Other Suppliers?

We are professional equipment manufacturer, Our service as below: 1. Factory supply directly 2. 12 months warranty for the whole machine 3. Friendly English version manual and operation video 5. Engineer available to service machinery overs.

What Services Can We Provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW; Accepted Payment Currency:USD,EUR,CNY.

How To Choose A Suitable Machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. It can be customized according to your requirements.

Do You Have A Setup And Equipment Commissioning Service?

Yes,we have. The machine was installed and debugged before delivery. You can use the machine directly after receiving it. Of course, we also could let our technologists go to your country to install and debug.