Products

Fiber plate cutting machine with dual exchange table system

Fiber plate cutting machine with dual exchange table system: Seamless table switching, zero downtime between loading/unloading. Boosts fiber plate cutting efficiency by 50%+, ideal for high-volume production.

Brand:Gain

Product origin:Weifang,Shandong,China

Delivery time:7-30 days

Supply capacity:500 units/year

Send Inquiry

Product Description

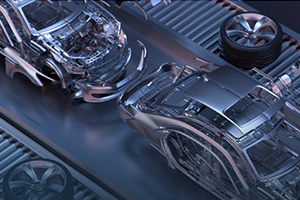

Non-Stop Production with Dual Exchange Tables

Dual parallel worktables (each supporting 1220×2440mm–2000×6000mm sheets) enable simultaneous cutting and loading/unloading. Table exchange takes only 15–20 seconds via servo-driven translation rails, eliminating downtime between batches and boosting overall productivity by 60% compared to single-table models.

Heavy-Duty Table Load-Bearing Capacity

Each exchange table features a reinforced steel frame with a load capacity of 800–1500kg (depending on size), supporting thick plates up to 30mm (carbon steel) and 20mm (stainless steel) without deformation. The table surface is covered with wear-resistant ceramic strips to protect against scratches and extend service life.

High-Precision Synchronous Drive System

X/Y axes adopt dual-motor rack-and-pinion drives with electronic gear synchronization, achieving positioning accuracy of ±0.02mm/m and repeatability of ±0.01mm. The exchange table’s linear guide rails (imported from THK/Hiwin) ensure table positioning error ≤0.03mm, guaranteeing consistent cut quality across both tables.

Intelligent Table Exchange Control

Integrated with the 19-inch industrial CNC system, the dual-table operation supports pre-programmed table switching logic. Features collision avoidance sensors and automatic table leveling (via precision sensors) to prevent damage during exchange, reducing operational errors by 90%.

Versatile Fiber Laser Power Options

Equipped with 1000W–12000W high-brightness fiber laser sources (IPG/Raycus optional), delivering cutting speeds up to 150m/min for 1mm stainless steel. The laser’s stable output (power fluctuation ≤±1%) ensures smooth, burr-free edges (Ra ≤1.0μm) on both thin-gauge sheets and thick plates.

Application Scenarios: Covering Cutting Needs of Multiple Industries

Whether it is the cutting of precision titanium alloy parts in the aerospace field, the blanking of stainless steel plates in automotive manufacturing, the engraving of acrylic letter molds in the advertising industry, or the micro-hole cutting of PCB boards in the electronics industry, this laser cutting machine can easily handle it. For thin plate cutting, its advantages of high speed and high efficiency can realize mass production; for thick plate cutting, its stable power output can ensure the quality of the cutting edge, truly achieving "both thin and thick plate cutting". Currently, the equipment has been widely used in more than 20 industries such as mechanical processing, hardware manufacturing, and home decoration, and has become the first choice for many enterprises to upgrade their cutting processes.

FAQ

How To Use The Machine After Receving The Machine?

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we will send you user manual or videos before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

Why Should You Buy From Us Not From Other Suppliers?

We are professional equipment manufacturer, Our service as below: 1. Factory supply directly 2. 12 months warranty for the whole machine 3. Friendly English version manual and operation video 5. Engineer available to service machinery overs.

What Services Can We Provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW; Accepted Payment Currency:USD,EUR,CNY.

How To Choose A Suitable Machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. It can be customized according to your requirements.

Do You Have A Setup And Equipment Commissioning Service?

Yes,we have. The machine was installed and debugged before delivery. You can use the machine directly after receiving it. Of course, we also could let our technologists go to your country to install and debug.