Products

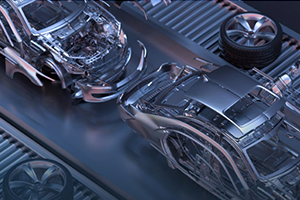

Auto loading and unloading laser tube cutting machine

High-efficiency auto loading & unloading laser tube cutter. Seamless automation from feeding to cutting to unloading, boosting productivity by 30%+.Precision cutting (±0.1mm), handles diverse tubes (round/square/rectangular). Reduces labor costs, ensures consistent quality. Ideal for mass production in metalworking, automotive, and construction.

Brand:Gain

Product origin:Weifang,Shandong,China

Delivery time:7-30 days

Supply capacity:500 units/year

Send Inquiry

Product Description

Fully Automatic Loading & Unloading System: Free Manpower, Boost Productivity

The intelligent auto loading & unloading unit equipped with the equipment is the core key to efficiency improvement. The feeding end adopts a hydraulic material rack, which can carry 50-300 tubes of different specifications at one time (tube diameter range φ16mm-φ220mm, length 3m-6m). The infrared tube alignment sensor automatically identifies the tube position, and the servo feeding arm accurately grabs and feeds it into the cutting area. The entire feeding process only takes 8 seconds, without manual handling and alignment.

After cutting, the graded automatic material collection system can sort finished parts and waste materials according to preset programs: finished products with length ≥500mm are conveyed to the finished product rack through the conveying roller table; small tube parts fall into the special collection box; waste materials are automatically guided into the waste bin through the inclined discharge port. This realizes the fully unmanned operation from raw material feeding to finished product storage. Compared with the traditional manual loading and unloading mode, a single equipment can reduce 2-3 operators, and the production efficiency is increased by more than 60%, which is especially suitable for mass production scenarios with a daily output of ≥500 tubes.

Core Tube Cutting Technology: Dual Breakthroughs in Precision and Adaptability

In terms of cutting performance, the equipment is equipped with an IPG/Ruike high-power fiber laser (power optional 1000W-4000W), combined with a 3D dynamic focusing laser head specially designed for tube processing. It can realize various processing technologies such as tube cutting, grooving, chamfering, drilling, and bevel cutting. The perpendicularity error of the cutting edge is ≤0.1mm/m, and the roughness of the cutting surface is Ra≤1.6μm, which can be directly used for assembly without subsequent secondary processing.

Aiming at the characteristics of different tubes, the equipment has strong adaptability: whether it is metal tubes such as carbon steel, stainless steel, and aluminum alloy, or non-metal tubes such as PVC and PPR, the automatic tube diameter recognition system can real-time detect the tube diameter and roundness, and intelligently adjust laser power, cutting speed and auxiliary gas parameters (air, oxygen, nitrogen can be switched automatically). The specially equipped anti-shake clamping jaw device adopts a flexible rubber chuck, which can effectively avoid deformation when clamping the tube. Even for thin-walled tubes (wall thickness ≥0.8mm) or special-shaped tubes (square tubes, rectangular tubes, elliptical tubes), it can ensure stable cutting precision.

Intelligent Control System: Convenient Operation, Efficient Management

In terms of operation and management, the equipment is equipped with a 19-inch high-definition touch screen, and a dedicated tube cutting software developed based on the Windows system. It supports direct CAD graphics import, parametric programming and 3D simulation cutting functions. Operators can preview the processing effect through the screen and avoid programming errors in advance. The software has a built-in database of over 2000 industry standard processes, covering common tube processing parameters such as scaffold tubes, furniture legs, and auto exhaust pipes, allowing novices to get started quickly.

To meet the intelligent management needs of factories, the system supports MES production management system docking, which can real-time upload data such as production quantity, pass rate, and equipment operating status. Managers can remotely check the production progress through computers or mobile phones. At the same time, the equipment has a breakpoint resume cutting function. In case of sudden power failure or emergency shutdown, it can continue processing from the breakpoint after restart, avoiding raw material waste. In addition, the intelligent diagnosis module can real-time monitor more than 20 key parameters such as laser head position, feeding precision, and gas pressure. When an abnormality occurs, it will automatically alarm and push fault solutions, and the comprehensive equipment utilization rate can reach more than 95%.

Application Scenarios: Full Coverage of Tube Processing in All Industries

From round tube cutting and square tube grooving in steel structure projects, to bevel cutting of table and chair legs and drilling of handrails in the furniture industry, to special-shaped incision processing of exhaust pipes in the automotive industry and pre-bending processing of tubes for fitness equipment, this auto loading & unloading laser tube cutting machine can be accurately adapted. For bulk orders, its fully automatic process can realize 24-hour continuous production; for customized small-batch orders, its quick changeover capability (changeover time ≤10 minutes) can greatly shorten the production cycle. Currently, the equipment has served more than 1,000 tube processing enterprises, helping customers achieve significant benefits of 30% lower processing costs and 40% shorter delivery cycles.

FAQ

How To Use The Machine After Receving The Machine?

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we will send you user manual or videos before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

Why Should You Buy From Us Not From Other Suppliers?

We are professional equipment manufacturer, Our service as below: 1. Factory supply directly 2. 12 months warranty for the whole machine 3. Friendly English version manual and operation video 5. Engineer available to service machinery overs.

What Services Can We Provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW; Accepted Payment Currency:USD,EUR,CNY.

How To Choose A Suitable Machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. It can be customized according to your requirements.

Do You Have A Setup And Equipment Commissioning Service?

Yes,we have. The machine was installed and debugged before delivery. You can use the machine directly after receiving it. Of course, we also could let our technologists go to your country to install and debug.