Products

Combined plate and tube laser cutting machine

This combined laser cutter excels at dual tasks: smooth plate cutting and accurate tube/pipe cutting (including circumferential cuts). Advanced CNC controls ensure stable positioning and consistent results. Boosts productivity by streamlining workflow for mixed metal processing needs.

Brand:Gain

Product origin:Weifang,Shandong,China

Delivery time:7-30 days

Supply capacity:500 units/year

Send Inquiry

Product Description

All-in-One Dual-Processing Capability

Integrates professional plate cutting and high-precision tube processing in a single system, eliminating the need for two independent machines. Handles plates of 1220×2440mm–3000×12000mm (thickness 0.5–30mm for carbon steel) and tubes (φ15–200mm round, 15×15–180×180mm square, 15×30–160×250mm rectangular) with wall thickness 0.8–18mm, saving workshop space by 50% and reducing equipment investment by 30%.

High-Performance Tube Rotary Axis

Equipped with a servo-driven 360° rotary axis and 4-jaw self-centering chuck, delivering rotation accuracy of ±0.008° and maximum speed of 100rpm. Supports 0–60° bevel cutting, spiral groove machining, and complex 3D contour cutting on tubes, with edge roughness Ra ≤1.0μm—no secondary deburring required even for precision pipe fittings.

Seamless Dual-Mode Switching

Adopts an electric retractable rotary unit design that automatically stows under the worktable when processing plates, avoiding spatial interference. The CNC system enables one-click switching between plate and tube modes in 2–3 minutes, ensuring continuous production and boosting machine utilization rate to over 92%.

Heavy-Duty Structure for Stable Operation

One-piece cast-iron or welded steel bed undergoes triple aging treatment (vibration, thermal, natural) to eliminate internal stress, with a load-bearing capacity of 800kg/m² for heavy plate cutting. X/Y/Z axes use imported linear guides and dual-motor drives, achieving plate positioning accuracy of ±0.015mm/m and repeatability of ±0.008mm.

Intelligent Unified Control System

19-inch industrial touchscreen paired with premium CNC (Siemens/Fagor optional) integrates advanced plate nesting (material utilization up to 96%) and tube cutting programming. Supports real-time 3D simulation, automatic parameter matching (100+ material libraries), and remote diagnostic via IoT, cutting programming time by 70% and error rate by 90%.

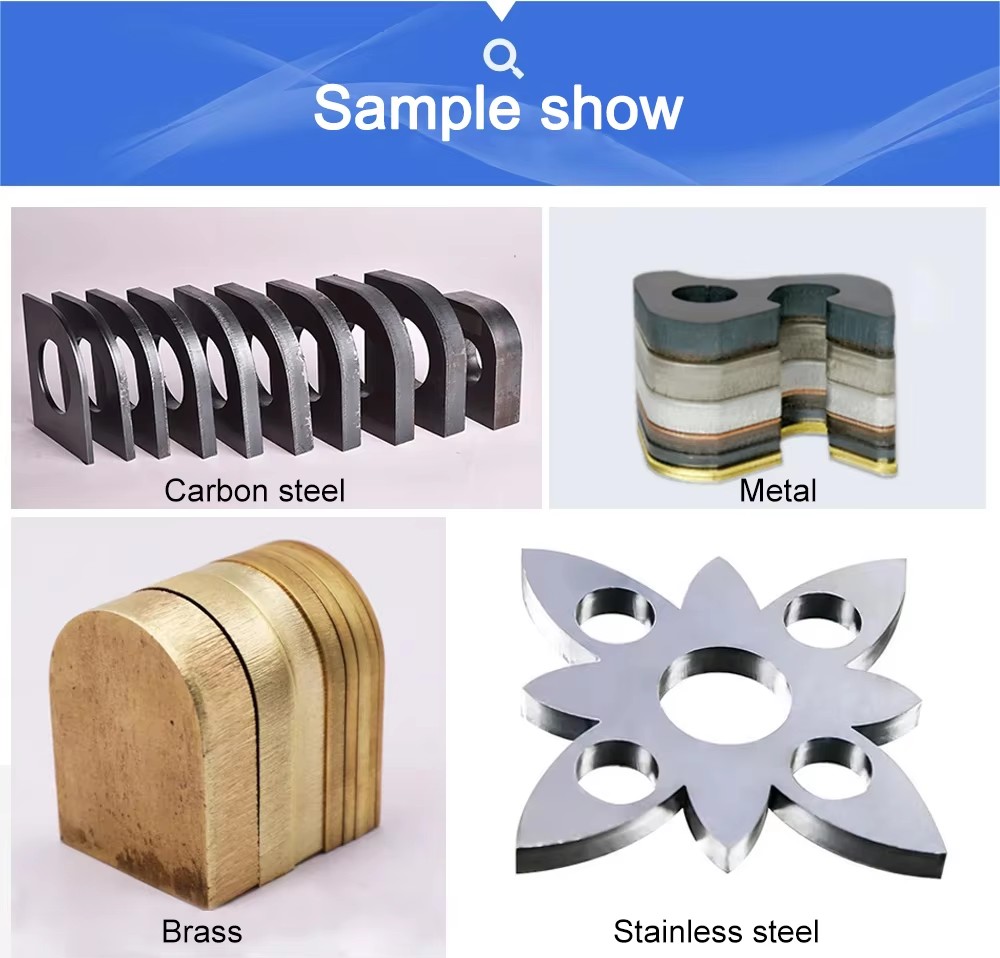

Sample Display

Packaging

Full-membrane packaging machine; anti-collision packaging edges; fumigation-free plywood crates and pallets with iron strapping.

FAQ

How To Use The Machine After Receving The Machine?

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we will send you user manual or videos before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

Why Should You Buy From Us Not From Other Suppliers?

We are professional equipment manufacturer, Our service as below: 1. Factory supply directly 2. 12 months warranty for the whole machine 3. Friendly English version manual and operation video 5. Engineer available to service machinery overs.

What Services Can We Provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW; Accepted Payment Currency:USD,EUR,CNY.

How To Choose A Suitable Machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. It can be customized according to your requirements.

Do You Have A Setup And Equipment Commissioning Service?

Yes,we have. The machine was installed and debugged before delivery. You can use the machine directly after receiving it. Of course, we also could let our technologists go to your country to install and debug.