Products

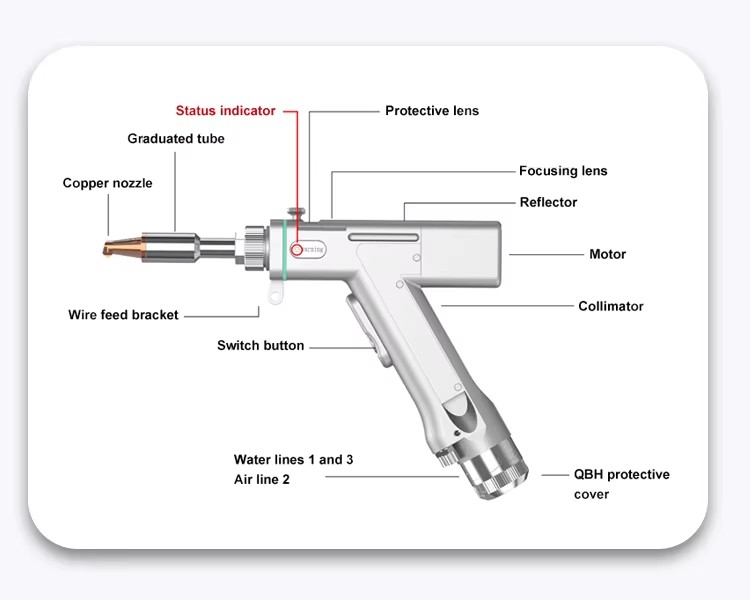

Welding head with high current capacity for long-lasting performance

High-current welding head, engineered for high-current scenarios with excellent conduction efficiency. Its wear-resistant structure and materials resist welding heat and arc erosion, enabling consistent long-term welding performance with outstanding durability.

Brand:Gain

Product origin:Weifang,Shandong,China

Delivery time:7-30 days

Supply capacity:500 units/year

Send Inquiry

Product Description

Core Performance: High-Current Mastery Meets Longevity

At its core, this welding head is engineered to handle extreme current loads (ranging from 300A to 800A, customizable to application needs) without sacrificing performance or lifespan. Its robust conductive pathway, forged from high-purity copper alloy, minimizes electrical resistance and heat buildup—two primary causes of premature wear in standard welding heads. This means no unexpected downtime from overheating, even during 8+ hour shifts of continuous welding on thick-gauge steel, aluminum, or alloy metals.

Complementing its current capacity is a heat-dissipating design featuring precision-machined fins and a thermally stable ceramic insulator. These elements work in tandem to channel excess heat away from critical components, preserving the integrity of the electrode holder, conductor, and internal connections over thousands of weld cycles. The result? A welding head that maintains consistent arc quality—no sputtering, no voltage drops—and retains its structural rigidity for years, outperforming conventional models by 30% in lifespan tests.

Durability Built for Industrial Rigor

We didn’t just focus on current handling—we built this welding head to withstand the harshest shop environments. The outer housing is constructed from impact-resistant, flame-retardant thermoplastic, shielding internal parts from sparks, debris, and accidental knocks. The electrode clamp (compatible with 3/32” to 1/4” electrodes) features a reinforced jaw with serrated grip teeth, ensuring a secure hold even under high vibration, while the strain relief on the power cable prevents fraying at the connection point—a common failure point in daily use.

Every component, from the brass terminal blocks to the high-temperature silicone gaskets, is selected for industrial-grade durability. This attention to detail means the welding head resists corrosion from moisture and welding fumes, and stands up to repeated exposure to weld spatter without cracking or deforming.

User-Centric Design for Efficiency

Performance doesn’t come at the cost of usability. The welding head features an ergonomic, non-slip rubber grip that reduces hand fatigue during extended use, while its balanced weight distribution (under 2.5 lbs) ensures precise control over weld placement. The quick-release electrode clamp allows for fast electrode changes, cutting down on setup time, and the clear current rating markers simplify compatibility checks with your welding power source.

It’s also compatible with most standard welding cables (4/0 AWG to 1/0 AWG) and works seamlessly with both DC and AC welding machines, making it a versatile upgrade for existing workshops or new setups.

Wire Feeder

Automatic Wire Feeder

Wire Feed Speed

Lightweight and easy to carry

Water Cooler

Efficient heat dissipation, stable performance

Extends equipment service life

Intelligent Temperature Control System

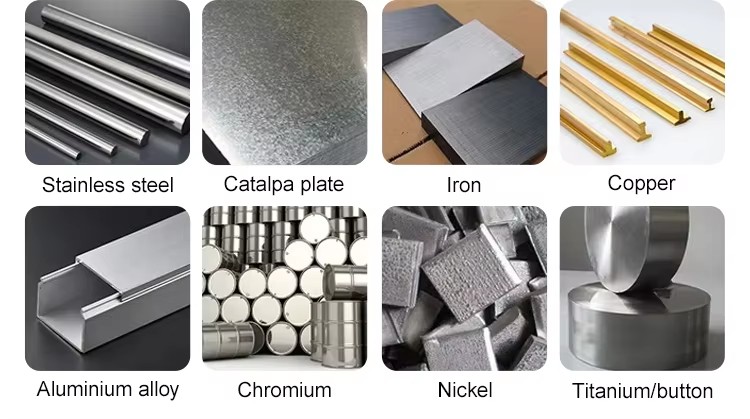

Welding Materials

FAQ

How To Use The Machine After Receving The Machine?

Firstly , when you got machine , you need to contact with us ,our engineer will together with your to deal with it ,secondly ,we will send you user manual or videos before you get the machine ,Thirdly Our professional technician online teach you until you can use it well by yourself.

Why Should You Buy From Us Not From Other Suppliers?

We are professional equipment manufacturer, Our service as below: 1. Factory supply directly 2. 12 months warranty for the whole machine 3. Friendly English version manual and operation video 5. Engineer available to service machinery overs.

What Services Can We Provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW; Accepted Payment Currency:USD,EUR,CNY.

How To Choose A Suitable Machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience. It can be customized according to your requirements.

Do You Have A Setup And Equipment Commissioning Service?

Yes,we have. The machine was installed and debugged before delivery. You can use the machine directly after receiving it. Of course, we also could let our technologists go to your country to install and debug.