Products

Portable laser welding machine for on-site repairs

The 5 in 1 handheld laser welding machine combines welding, cutting, cleaning, seam cleaning, and energy storage welding tasks. Its precision and efficiency make it easy to handle complex jobs without switching between devices. This handheld fiber laser welder is suitable for various materials and applications, offering comprehensive solutions for industrial manufacturing and repair.

Brand:Gain

Product origin:Weifang,Shandong,China

Delivery time:7-30 days

Supply capacity:500 units/year

Send Inquiry

Product Description

The features of a portable laser welding machine for on-site repairs

- Laser Welding

This fiber laser welding machine allows for precision laser welding of various materials, including metals like steel, aluminum, and copper. With the ability to deliver high-power laser output, it enables efficient and accurate welding operations. The handheld laser welding systems is easy to learn and operate, capable of producing high-quality welding results on various materials and thicknesses. The weld seams are smooth and aesthetically pleasing, requiring no secondary grinding or post-processing. The high-speed welding efficiency contributes to increased productivity. This handheld metal laser welding machine has 5-in-1 metal welding functions, including spot welding, seam welding, pulse welding, continuous welding and repair welding, which can meet a variety of welding needs.

- Laser Cleaning

The machine is also capable of laser cleaning, which is a non-abrasive method used to remove contaminants, rust removal, paint, and oxides from the surface of different materials. It offers a fast and efficient way to clean surfaces without damaging the underlying material.

- Laser Cutting

In addition to welding and cleaning, this machine can perform laser cutting operations. By focusing a high-power laser beam onto a specific area, it can cut through various materials with precision, including metals, plastics, and composites.

- Weld Seam Cleaning

After welding, there may be excess material, splatter, or contaminants on the weld surface or in the weld path. This function likely involves using laser energy to clean and prepare the weld area for subsequent passes or finishing.

- Energy Storage Welding

The energy storage welding function enables efficient welding in the professional energy storage and lithium battery industry by replacing specialized components. Whether it is metal parts processing or welding of battery electrodes, battery modules, battery covers and battery cases, users can complete different processes without switching between multiple machines, providing a cost-effective solution for new energy battery welding.

5 in 1 Fiber Laser Welding Cutting Cleaning Machine Features

- Five functions: This welders have three functions, including laser welding, cutting, cleaning, weld cleaning and energy storage welding, making them versatile tools for industrial applications.

- Portable design: This handheld laser welders are compact and portable, making them easy to carry and operate in different settings.

- High precision: This laser welders are capable of achieving high levels of precision, leading to accurate and aesthetically pleasing welds.

- Wide range of metal weldability: This handheld laser welding machines can weld a wide range of metals, including stainless steel, aluminum, copper, brass, titanium, and others.

- User-friendly control panel: 5 in 1 handheld laser welding systems feature a user-friendly control panel that is easy to understand and use, making it easy to adjust power and frequency settings.

- Safety features: To reduce the risk of accidents, these fiber handheld laser welders come equipped with various safety features that prevent damage to the machine or injury to the user.

Advanced Laser Source

User-friendly and efficient, achieving faster and more precise results than TIG/MIG welding!

Digital Control System

Adjust welding parameters with ease, and switch between multiple welding modes at will! From precise spot welding to continuous welding, ensure you get the best results and quality every time you weld. The system has a built-in library of process parameters for common materials and thicknesses, which can be quickly stored and recalled. Multi-functional intelligent touch screen, support multiple languages.

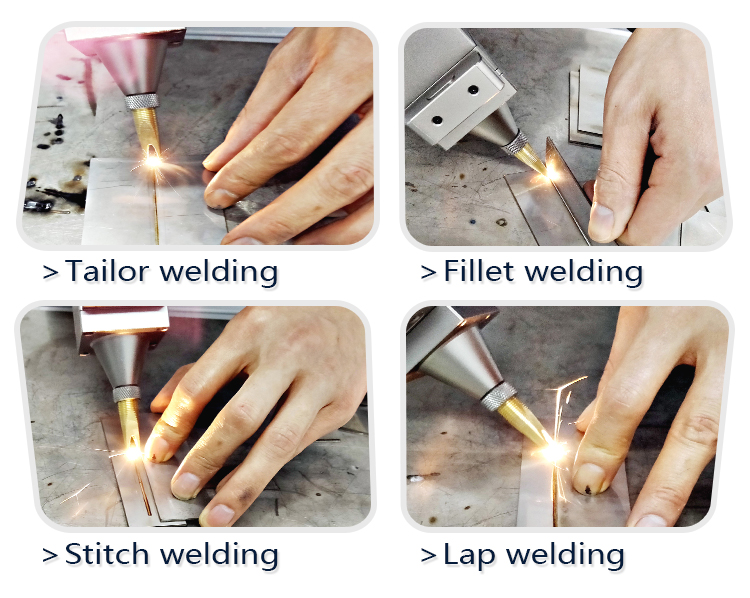

Handheld Laser Welding Mode

It supports multiple welding angles and techniques, including spot welding, seam welding, surfacing weld, groove weld, tee weld, and fillet weld, catering to diverse welding requirements.

FAQ

Are you a factory?

Yes, we have laser machine factory and the price is very competitive. We have after-sales technology to provide 24-hour service.

Which model should I choose?

Please tell us your materials, thickness, size, and the cutting objects (plates, tubes, etc) then we will provide you with professional suggestions.

If I do not know how to operate the fiber laser machine, how you can help me?

First, we have a detailed user manual and videos for your learning. Second, our engineers will provide you with technical support in time. If you want, we can provide you with training door to door.

How about the price? Can you make it cheaper?

The price depends on your configuration and requirements (function, size, quantity). Please contact us online now, our laser engineers can customize laser welding machine for your project.