Products

Automatic fiber laser welding machine for industrial use

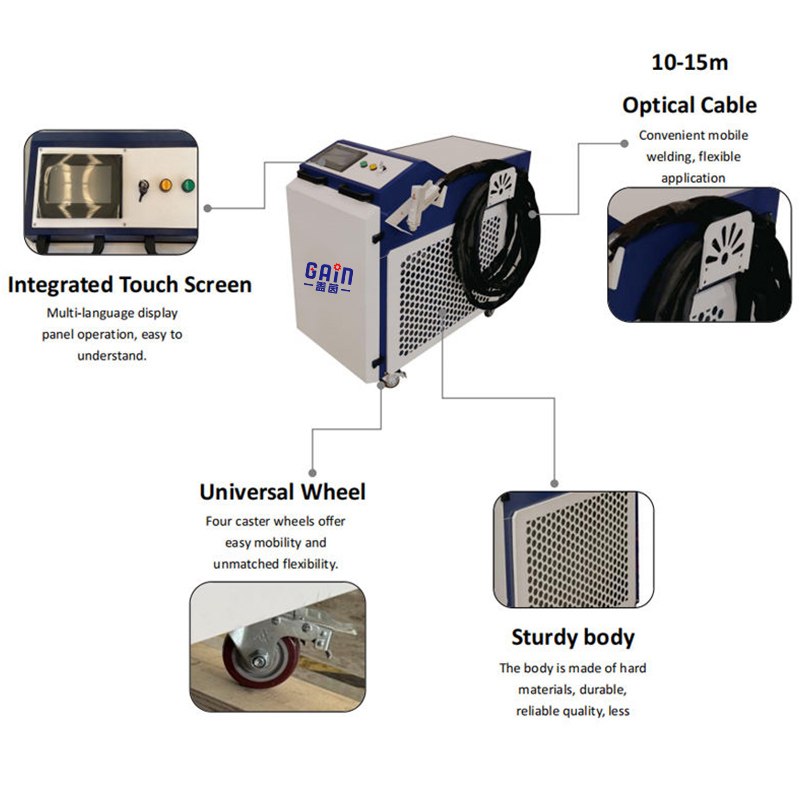

This portable handheld laser machine integrates welding, cutting, cleaning, and weld seam cleaning functions in one compact system. Equipped with a 1500W-3000W fiber laser and adopting a water-cooling design, it features stable performance and is suitable for materials such as stainless steel, carbon steel, aluminum, copper, and brass.

Brand:Gain

Product origin:Weifang,Shandong,China

Delivery time:7-30 days

Supply capacity:500 units/year

Send Inquiry

Product Description

Machine Configuration

This handheld welding machine is a new-generation welding solution that replaces traditional TIG welding and electric arc welding. Featuring a compact design, it is easy to operate and highly efficient, and is widely used for stainless steel, carbon steel, aluminum, galvanized sheets, and other metal materials. It integrates laser welding, laser cutting, laser cleaning, and seam cleaning in one compact system.

The split design and independent water cooling system provide faster welding speed and stronger welding performance. It is suitable for welding various functional metal materials, including carbon steel, stainless steel, galvanized aluminum, etc. It offers a wide range of welding directions and high welding efficiency, and can be used for welding small and micro parts.

Wire Feeder

Automatic Wire Feeder

Wire Feeding Speed

Lightweight and easy to carry

Water Cooler

Efficient heat dissipation and stable performance

Extends equipment lifespan

Intelligent Temperature Control System

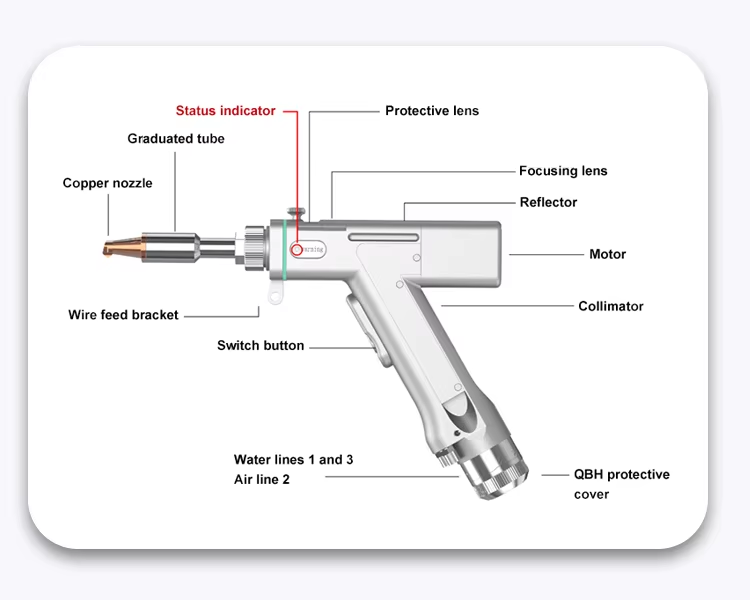

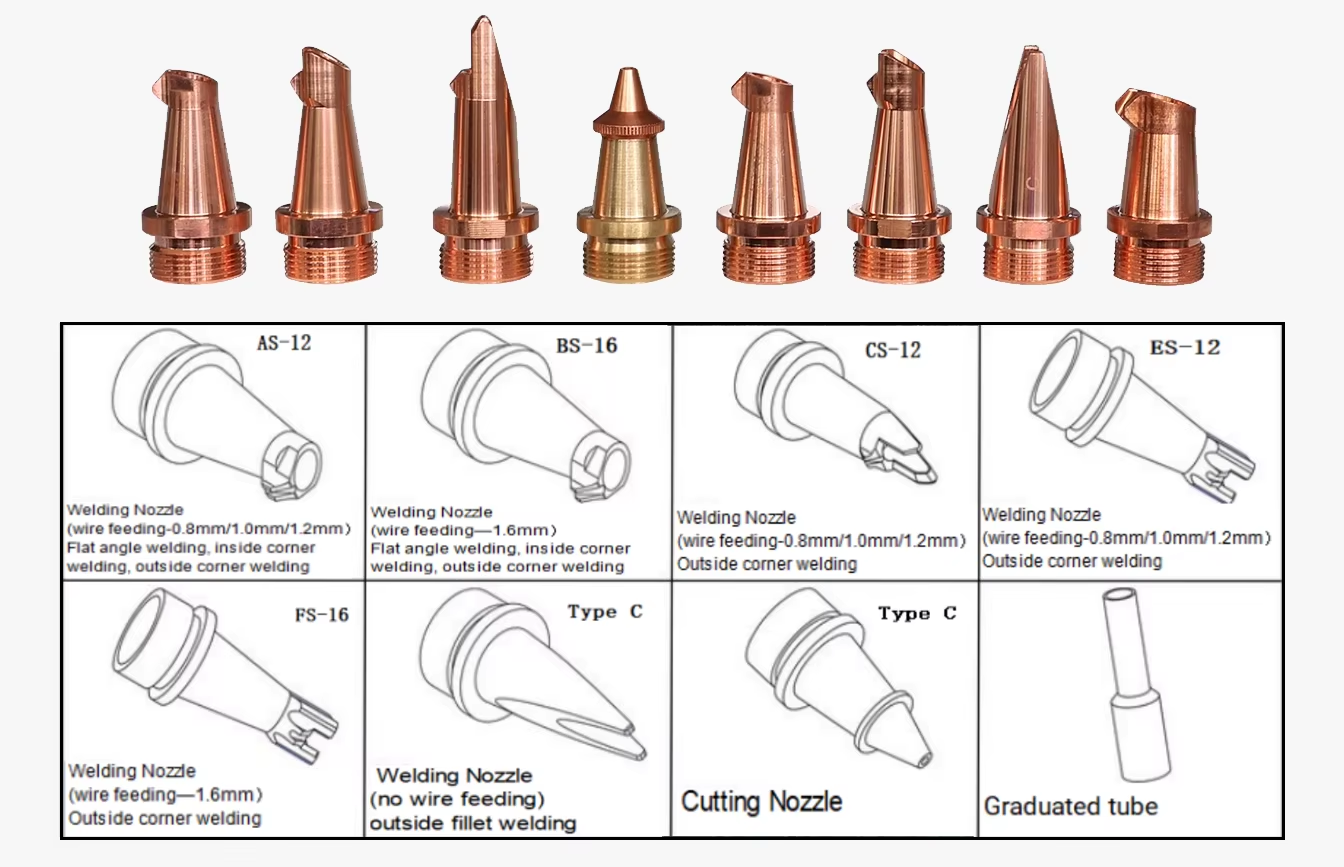

Copper Nozzle

Nozzle Types: The laser welding head can be fitted with a variety of nozzles, including angle nozzles and cleaning nozzles. These options allow for flexible welding of different products and handling of various materials.

Application Flexibility: The availability of different nozzles enhances the versatility of laser welding equipment, making it suitable for a wide range of materials and welding requirements.

Performance Optimization: The use of dedicated nozzles helps optimize the welding process by improving the control and precision of the laser beam.

Product Advantages

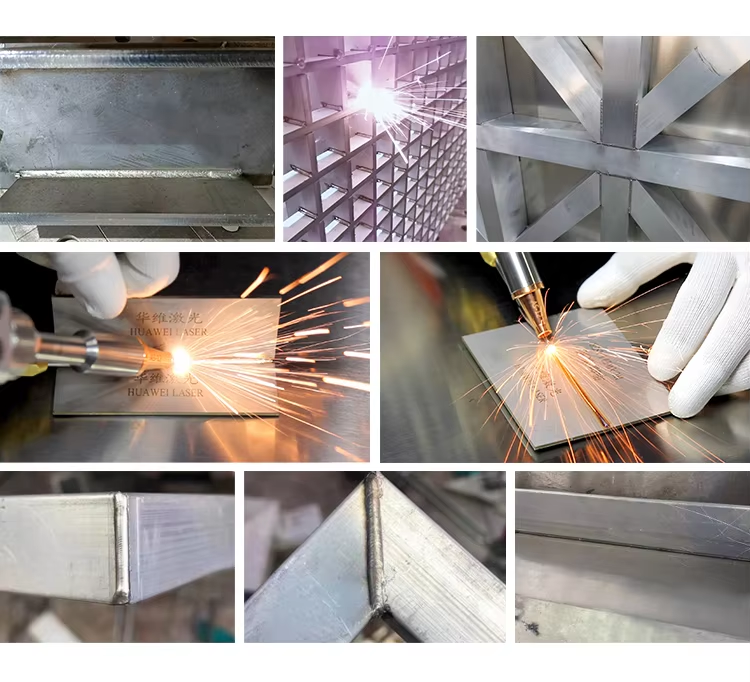

1.Excellent Welding Effect: Handheld laser welding adopts fusion welding with higher energy density. The welding area suffers almost no thermal shock and is not prone to deformation. The strength of the weld can reach or even exceed that of the base material itself.

2.High Speed & Low Deformation: Handheld laser welding features fast welding speed, a small heat-affected zone, and aesthetic, smooth welds with no or few pores. Its welding speed is 3-5 times that of TIG welding, enabling precision welding.

3.Integrated Operation: Handheld laser welding boasts the feature of integrated operation. It requires no additional brackets or equipment, is easy and convenient to operate, and is suitable for various welding tasks, enhancing flexibility and convenience.

4.Easy to Operate & Learn: Handheld laser welding is simple to operate and learn, saving labor costs. It is suitable for rapid training and onboarding.

Welded Sample

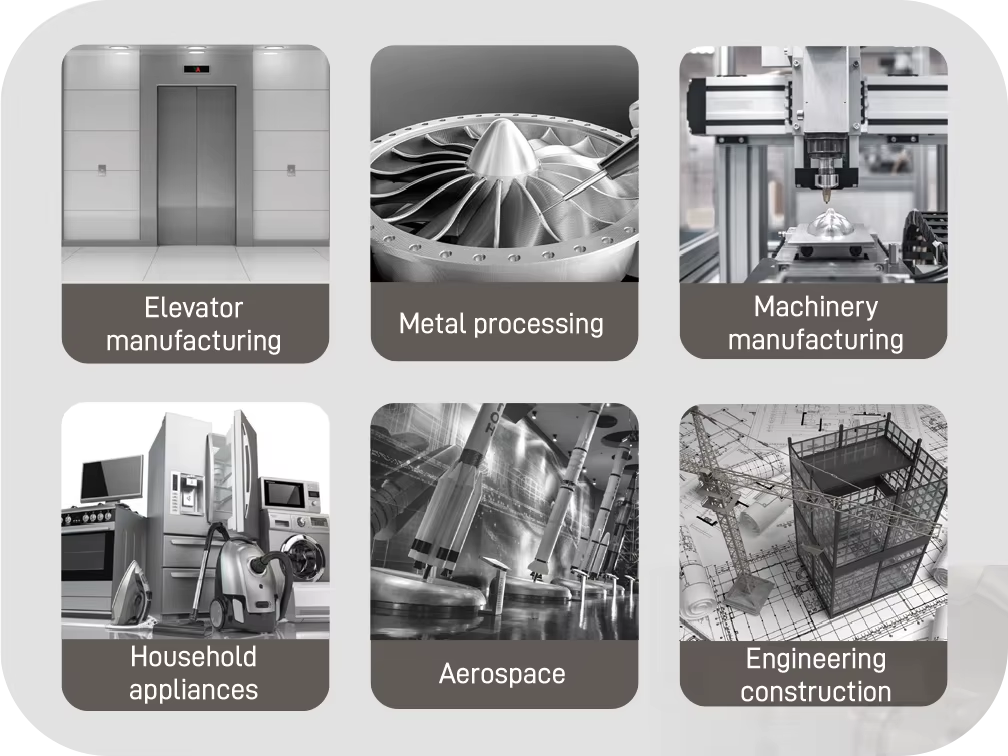

Application

FAQ

I don’t know which one suits me?

Please provide us with the following information:

Material and welding thickness: To match you with the appropriate laser generator power.

Industry: We have extensive sales experience and can offer recommendations for your specific sector.

I received the machine but don’t know how to use it. What should I do?

We will send training videos and an English manual along with the machine promptly. If you have further questions, we can communicate via phone or WhatsApp.

How to install and operate the machine?

Our technicians have already installed the machine before shipment. For the installation of some small parts, we will provide detailed training videos and a user manual with the machine. 95% of customers can learn to operate it independently.

What if the machine malfunctions?

In case of such issues, non-professionals should not attempt to repair the machine. Please contact us as soon as possible. We will resolve the problem for you within 24 hours.